Summary

- Instead of simply chasing corrugated packaging trends, companies that are intentional in their engineering, material choice, and design can achieve both sustainability and performance that stands the test of time.

- Winning companies leverage high-speed digital production, retail-ready design, and total cost of ownership analysis in their packaging strategy. These enable businesses to reduce waste, improve efficiency, and respond quickly to changing market demands.

- Working with packaging partners who offer integrated production, circular supply chain solutions, and packaging expertise is essential for maintaining supply stability, controlling costs, and turning packaging into a strategic advantage.

It’s amazing how much we expect from a simple box these days. Traditionally, a shipping container’s primary job was simply to get a product from Point A to Point B safely. Today, that same box is expected to do so much more. It needs to be a sustainability statement for your shareholders and a salesman for your brand on the retail shelf. And, crucially, it needs to be engineered to glide effortlessly through high-speed automated packers so production stays fast and efficient.

These rising expectations challenge operations and supply chain teams to manage increasingly complex demands. You’re probably feeling the pressure to be more agile with your graphics, more ambitious with your sustainability goals, all while keeping lead times short and costs under control. It’s a tall order.

To achieve these, it’s important not to simply follow trends in corrugated packaging. While trends can offer advantages that older approaches may struggle to provide, their impact is sometimes fleeting. Building a holistic strategy, however, helps you establish a foundation that can support your operations no matter which direction the industry goes.

At York Container, we’re seeing digital technology and material science come together in ways that make it easier than ever to hit all your targets at once, which means that the days of juggling trade-offs are behind us. In 2026, many companies will focus on finding that sweet spot where your sustainability goals, marketing needs, and production throughput finally align.

Corrugated Packaging Best Practices and Solutions to Pursue in 2026

Structural Engineering as a Huge Sustainability Metric

Many of the companies we work with care deeply about sustainability. Some face intense pressure to meet their Environmental, Social, and Governance (ESG) goals. The typical first step toward meeting their targets is to opt for packaging made from fully recycled materials.

But if you switch to recycled fiber, will the boxes hold up or get crushed? Historically, choosing recycled fiber occasionally involved compromises in box performance or added material to maintain durability. But this is no longer the case.

The most effective packaging strategies focus not just on the materials but on how the box is engineered. Companies now place greater emphasis on performance specifications, such as ensuring a box can survive a heavy stack in a humid warehouse.

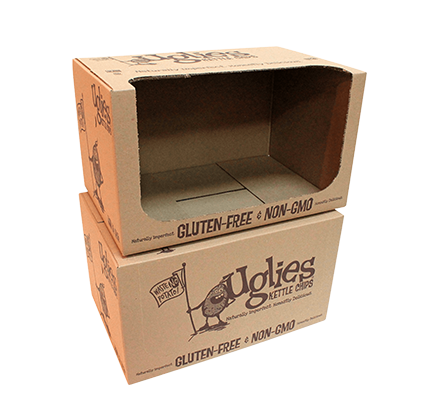

Right-Sized Shelf-Ready Packaging from York Container’s Portfolio

Because some products are heavy, fragile, or shipped stacked in humid warehouses, protecting them while keeping material use low requires precisely-engineered packaging designs to achieve the desired strength and optimize material use from the start.

A packaging partner can deliver that by following this process:

-

First, they run a simulation to model actual load conditions, such as stacking pressure, vibrations, and humidity changes.

-

Using those simulations, designers optimize the box’s flute type, liner thickness, and folding pattern for load-bearing strength instead of simply choosing a heavy, overbuilt material.

-

Designers strengthen high-stress areas, including corners, edges, and stacking surfaces, trimming material in less critical areas to maintain safety while using less fiber.

This approach gives packaging engineers some breathing room to get creative. Thanks to advanced software to simulate stress, it is now possible to design boxes that are sustainable while remaining strong in high-stress areas.

Plate-Free Agility

You’re planning for a seasonal promotion but you still have 50,000 outdated boxes in stock. What should you do?

For decades, high-graphic packaging was limited by the print plate.

Printing a high-quality branded box used to mean shelling out for expensive photopolymer plates for every color. Do you need to tweak a line on the back? Then you have to scrap the old plates, pay thousands for new ones, and wait weeks for the tooling to arrive.

Today, companies are ramping up their use of high-speed digital production. What started as a tool for prototypes has now scaled to full production. Digital presses print straight from a file, so there’s no need for plates or lengthy setup. That means you can produce 5,000 standard boxes in January and switch seamlessly to 5,000 Valentine’s Day boxes in February without stopping the line or paying for extra tooling.

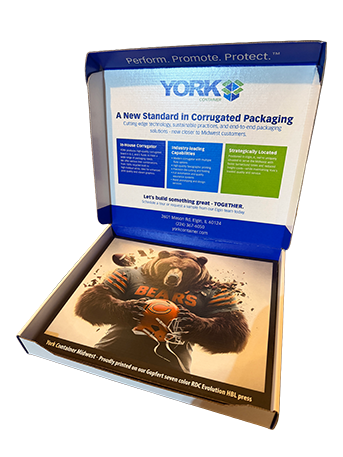

Custom Packaging from York Container’s Portfolio

High-speed digital production impacts operations in several ways. For instance:

-

Companies can move to a just-in-time model, ordering only what they need for the coming weeks instead of storing six months of packaging.

-

If regulations change or marketing updates a label, you update the file instead of discarding pallets of incorrect boxes.

-

Corrugated packaging trends can be acted on immediately, allowing products to reach retail shelves in days rather than months.

Packaging Engineered for Performance and Shelf Appeal

According to a study, 72% of consumers say packaging influences their purchase decision. Packaging doesn’t just affect shelf‑appeal, it actually drives buying behavior.

With that in mind, retail-ready packaging needs to do more beyond containing products. It must:

-

Open quickly so store associates can set up displays without delay

-

Transform into a clean and branded display to make the product instantly appealing on the shelf

-

Reduce effort for store staff to minimize handling errors and restocking time

-

Support sustainability goals by using recyclable or lighter materials without compromising strength

-

Work for both in-store presentation and e-commerce shipping

Integrating these principles creates a container that works as hard for the logistics team as it does for the customer.

Custom Corrugated Tray-Pack from York Container’s Portfolio

Shifting Focus from Price to Total Cost of Ownership

It’s easy to focus on the cost per box when evaluating packaging choices, but you know that the real story goes beyond the price on the quote sheet. A corrugated box that seems inexpensive can actually increase your costs if it causes line stoppages, needs extra tape, or increases shipping weight even slightly.

To truly get the most out of your packaging investment, it pays to take a step back and look at packaging through a holistic lens. Instead of comparing standard box prices, look at how packaging performs throughout your entire system.

Take a moment to ask yourself:

-

Is the box oversized and forces you to fill a big empty space with extra material?

-

Are you paying more in shipping because of unnecessary weight or wasted space?

-

Does the box design slow down your packers or production lines?

When you consider the total cost of ownership, your focus moves from shaving pennies per box to identifying substantial cost reductions, sometimes tens or even hundreds of thousands of dollars in freight, labor, and process improvements.

Corrugated Packaging that Supports the Circular Supply Chain

For decades, packaging followed a simple and linear path. You purchased a box, used it, and then paid a waste management company to remove it. Today, more companies are rethinking the traditional approach and looking for ways to keep materials moving in a closed loop instead of letting them leave the system for good.

A growing number of brands are partnering with corrugated packaging suppliers who also operate the paper mills behind their packaging. This approach offers more than predictable pricing. It gives you supply stability and creates a true circular process where yesterday’s corrugated waste becomes tomorrow’s raw material.

In other words, the fiber you recover can return as part of your next order, and you know it comes from a partner genuinely committed to sustainability instead of just meeting minimum recycling standards.

You can also quickly reap the benefits of this process. First, your supply chain becomes more resilient during tight markets because your partner isn’t relying solely on open-market allocations. Price swings become less disruptive. And your sustainability goals become easier to track and measure, since your packaging participates in a continuous cycle of reuse instead of a one-and-done system.

Make Every Packaging Choice Count

It’s helpful to understand where the industry is headed, but what really matters is how these shifts show up in your day-to-day operations and your costs. If you’re aiming for faster inventory turnover, digital printing can help you run smaller batches more often, so you’re not tying up cash in months of packaging you don’t need yet.

If controlling freight costs is a priority, structural right-sizing makes a measurable difference. Meanwhile, using data to refine your box dimensions lets you ship more units per truck and reduce the amount of space you pay for.

If you want smoother and faster lines, retail-ready designs support that goal. Packaging that’s easier to open and handle reduces labor time per unit and keeps production flowing.

And as you plan for the next 18 months, one shift is especially important. Extended Producer Responsibility (EPR) regulations are moving toward making brands financially accountable for the waste their packaging creates. That means non-recyclable materials may carry higher fees in the future. Moving to a recycled and circular corrugated solution now is one of the most effective ways to protect your business from those upcoming costs.

As these shifts take hold, your supplier’s capabilities become a deciding factor in your success. Here are a few questions that can help you gauge their readiness:

-

Can they run high-quality digital printing for smaller runs, so you can launch promotions quickly without paying for expensive plates or tooling?

-

Do they offer vertically integrated production, including access to their own paper mills, to ensure supply stability during market fluctuations?

-

Can they design retail-ready or custom boxes that protect your product and present it beautifully on the shelf?

-

Can they perform a comprehensive packaging review to optimize your line, reduce labor, minimize waste, and improve overall efficiency?

Packaging is no longer a basic commodity. Every choice, from the strength of the paper to the way the box opens, affects your operation more than most people realize. If you’re ready to stop working around limitations and start building an advantage, contact York Container today to schedule a consultation and explore how your packaging can drive efficiency, sustainability, and business results.

FAQs About Corrugated Packaging Trends and Design

Q: The post suggests switching to recycled fiber but I worry about durability. How can we be sure the boxes will not collapse?

A: Structural engineers use advanced simulation software to model the pressure your boxes will face. They analyze factors such as warehouse humidity and stacking weight to reinforce the corners and edges that bear the most load.

Q: Digital printing sounds great for marketing but is it practical for regular supply chain needs?

A: Digital production allows you to move to a just-in-time inventory model. You print only the specific quantity you need for the coming weeks and eliminate the cost of storing months of excess packaging. This method also lets you update graphics immediately if regulations change so you never have to throw away outdated boxes.

Q: You mentioned looking beyond the price per box. What specific hidden costs should we look for?

A: A cheaper box often costs you more in other areas such as freight and labor. You should calculate how much you spend on shipping air in oversized boxes or dealing with line jams caused by poor construction. Investing in a precise corrugated packaging design helps you fit more units on a truck and keeps your automated packers running without interruption.